Haith recognised that the industry needed a more robust and reliable box tipping system, so our R&D team was set a task of designing a new concept, it had to be high capacity, robust, reliable, virtually maintenance free and would totally empty the box.

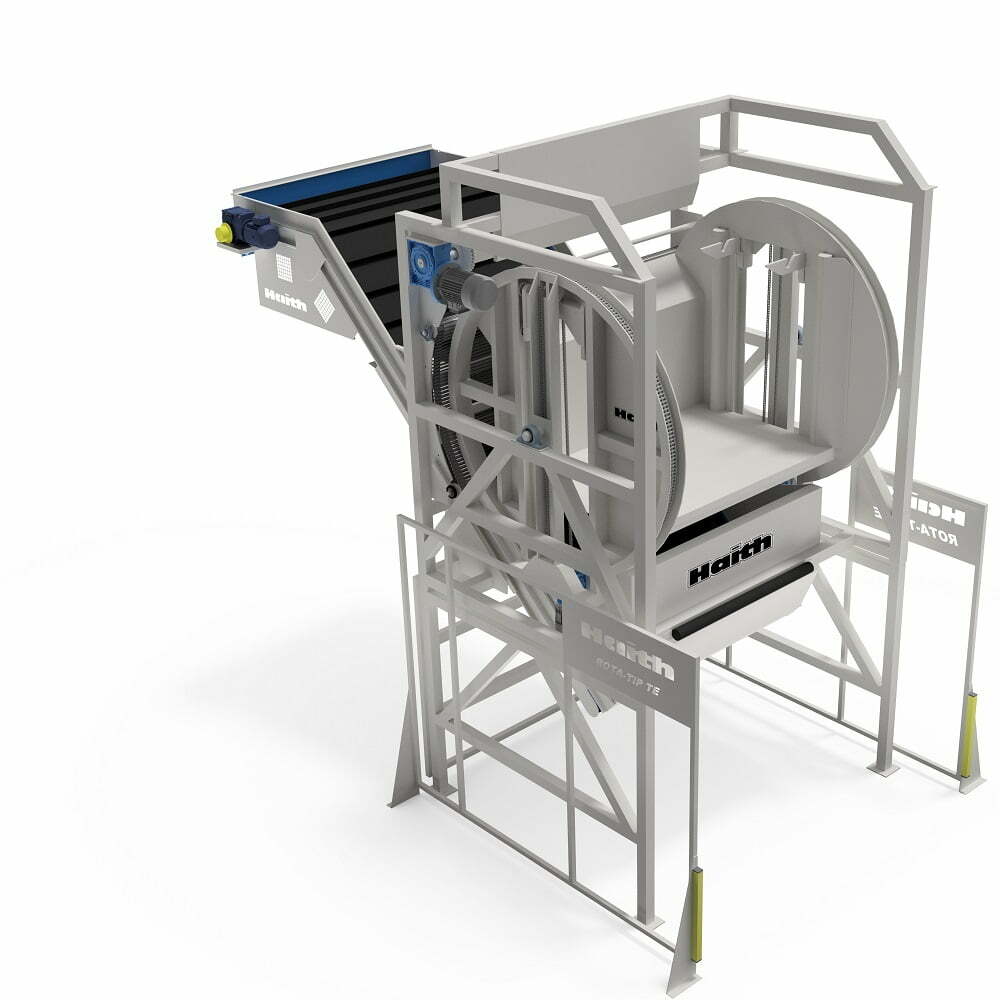

The RotaTip was the outcome, this machine has been designed to handle the toughest of environments, fully empties the box and, most of all, is gentle on the crop while working at a high capacity.

The tippler is rotated around a centre pivot, which means the weight of the box is never lifted and the machine is not put under any pressure, thereby eliminating fatigue or damage to the machine and the box. Haith has also incorporated a continental web on the machine, which forms a lid on the box as it rotated, to ensure the crop isn’t scuffed when it is transferred.

The Rota-Tip has no hydraulics so there is no possibility of oil contamination to the vegetables. All motors are high efficiency and unlike existing hydraulic tippers where the motors run constantly even when idling the Rota-Tip motors only run when the tipping sequence is activated giving a great saving in power usage.

The Haith Rota-Tip has proved to be a firm favourite with vegetable packers, since its introduction into the global tippler market with over 180 machines sold worldwide, this is testament to it’s robust, gentle and reliable design making the Rota-Tip the obvious choice when packers are looking for a machine that can stand up to the constant rigors of front of line box handling.

Speak to our specialists

Call us on 01302 831911 and chat to a member of our team for more information about our industrial food handling equipment.

Standard features

- Fully automatic control

- Duplex chain drive on tipping drum

- Active holding web to prevent scuffing of crop

- Electrically powered lift to eject box

- Safety beams at entry points

- Full width produce discharge belt - length & angle to suit line configuration

- Touch screen HMI control

- Extended warranty

- Integral buffer hopper maintains line speed

- Reduced forklift movements

Optional features

- Mobile version

- Stainless or mild steel construction

- XL version - tips bins up to 4 tonnes

- Wide tipping cradle - can tip wider bins or two smaller bins

Here at Haith we are proud to say that we are one of the only companies in our sector to be continuously owned by the same family since the company was founded.

It all began when, at 18 years old, Geoff Haith started carrying out repairs for local farmers leading him to realise that there was a need for a more mechanised way of washing and grading root vegetables, with his engineering ability and farming background he designed and manufactured machines for carrot, potato and beetroot handling.

The business, until recently, has been run by Geoff’s five sons and daughter, backed by a great young management team to ensure the continued success of the company, there are over 120 people employed at our factory in the UK and multiple agents around the world promoting the Haith brand globally resulting in a network of excellent installations and satisfied customers worldwide.

Haith has continued to grow in size and strength and has moved on 3 occasions to larger premises with more production area, this has led to the present ultra-modern wholly owned facility with around 6,000 m² of production space on a 6 acre site in South Yorkshire which is equipped with the most up to date CNC laser, waterjet and bending equipment.

Haith have achieved many awards for machine design over the years and are especially proud to have twice been awarded the highest accolade in the UK, The Queen’s Award for Enterprise, both times in the Innovation category, as the only company in the field to hold this prestigious award, Haith’s emphasis on continual innovation and development with a view to keeping the UK vegetable industry at the forefront of technology has been acknowledged.

Request more information

on this machine

Speak to our specialists

Call us on 01302 831911 and chat to a member of our team for more information about our industrial food handling equipment.