Details

Features

Gallery

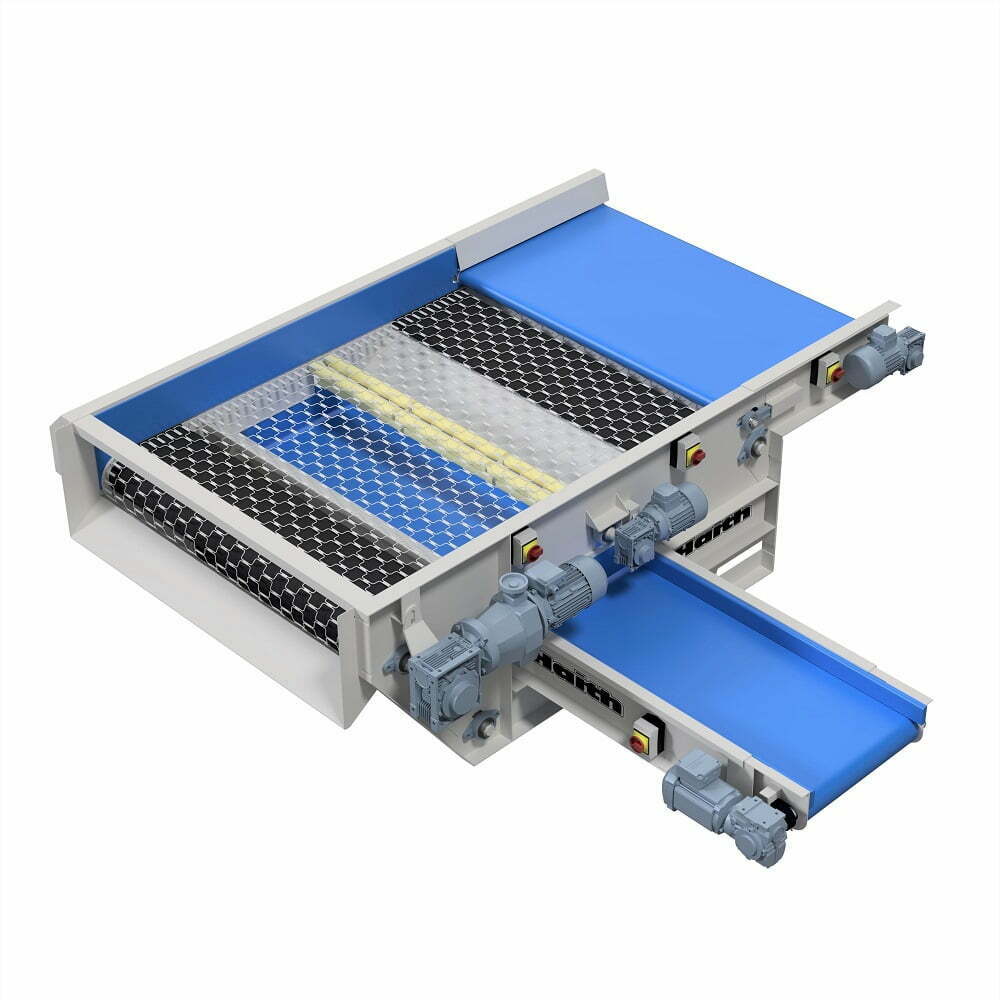

Our Screen Bit Remover continuously removes broken fragments of crop and debris from the produce flow.

Produce, such as carrots and potatoes are transferred onto a traveling screen with a set size aperture. As the screen is conveyed forward, two full-width agitators gently move the crop causing any bits and debris to drop on to a waste conveyor below where the produce is taken over the end. The screen and agitator speeds are variably controlled individually to suit the various crop conditions.

Each individual roller can be removed without taking the screen off, this makes the machine very easy to maintain and keeps down time to a minimum.

Standard features

- Variable speed 3 phase geared motor

- Adjustable safety clutch

- Fully enclosed chain drive to both drums

- Anti-plugging board at infeed and end of machine

- Tubular support frame to raise machine

Optional features

- Infeed conveyor

Request more information

on this machine