Haith have been building screen graders since the 1960’s and over the decades have become renowned for them. This is due to the continuous development into what is now a robust, low maintenance machine.

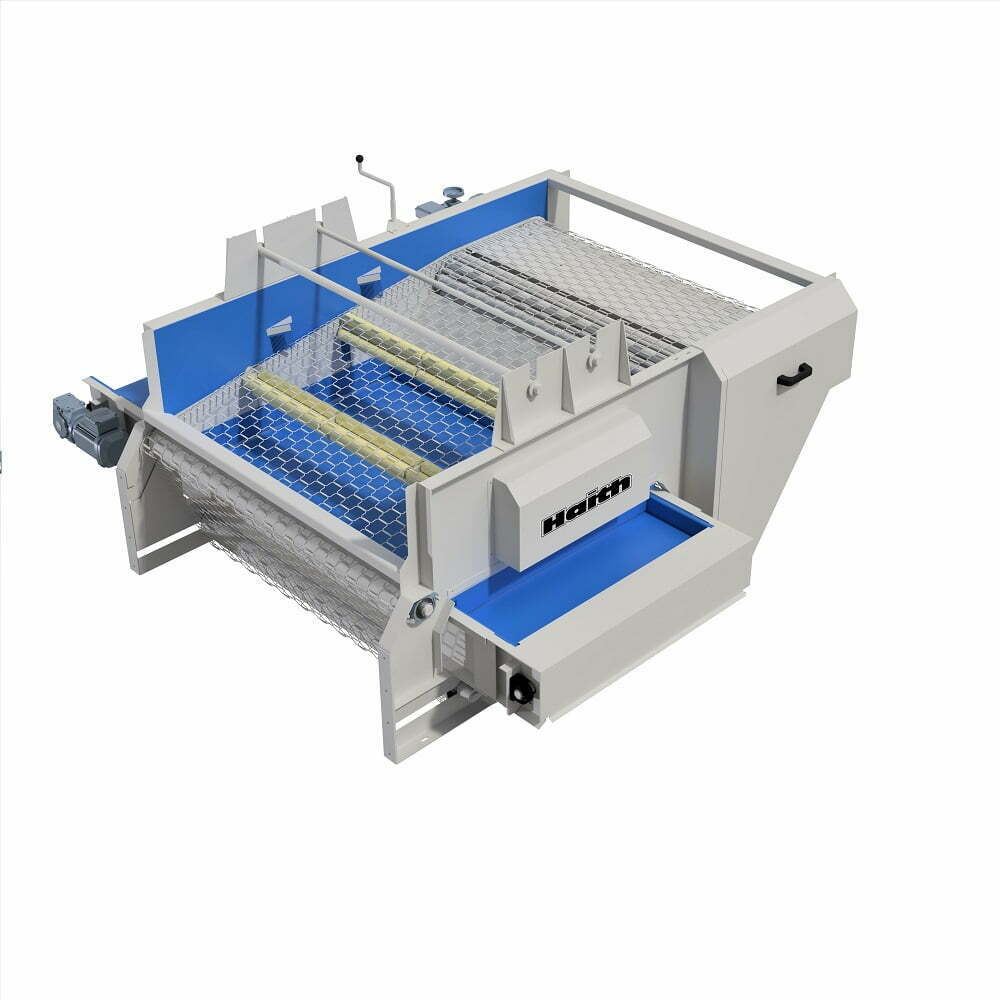

Round or oval produce, such as potatoes and onions, are transferred onto a traveling grading screen with a set size aperture. As the screen is conveyed forward, two full-width agitator shafts disturb the crop causing any undersize to drop on to a conveyor below and the oversize to progress over the end. The screen and agitator speeds are variably controlled individually to suit the various crop conditions.

The machines can operate individually or as part of a bespoke system with multiple screen configurations.

Each individual roller can be removed without taking the screen off, this makes the machine very easy to maintain and keeps down time to a minimum.

Standard features

- Heavy-duty chassis

- Variable speed shaft mounted drives

- Crop unplugging roller

- Dual driven rollers give optimum screen drive

- Integral safety clutch

- Star transfer roller

- Twin agitators as standard

Optional features

- Single or triple agitators

- Screen changer to store additional screen

- Anti-block sensor to avoid web damage

- Stainless or mild steel construction

Request more information

on this machine