Details

Features

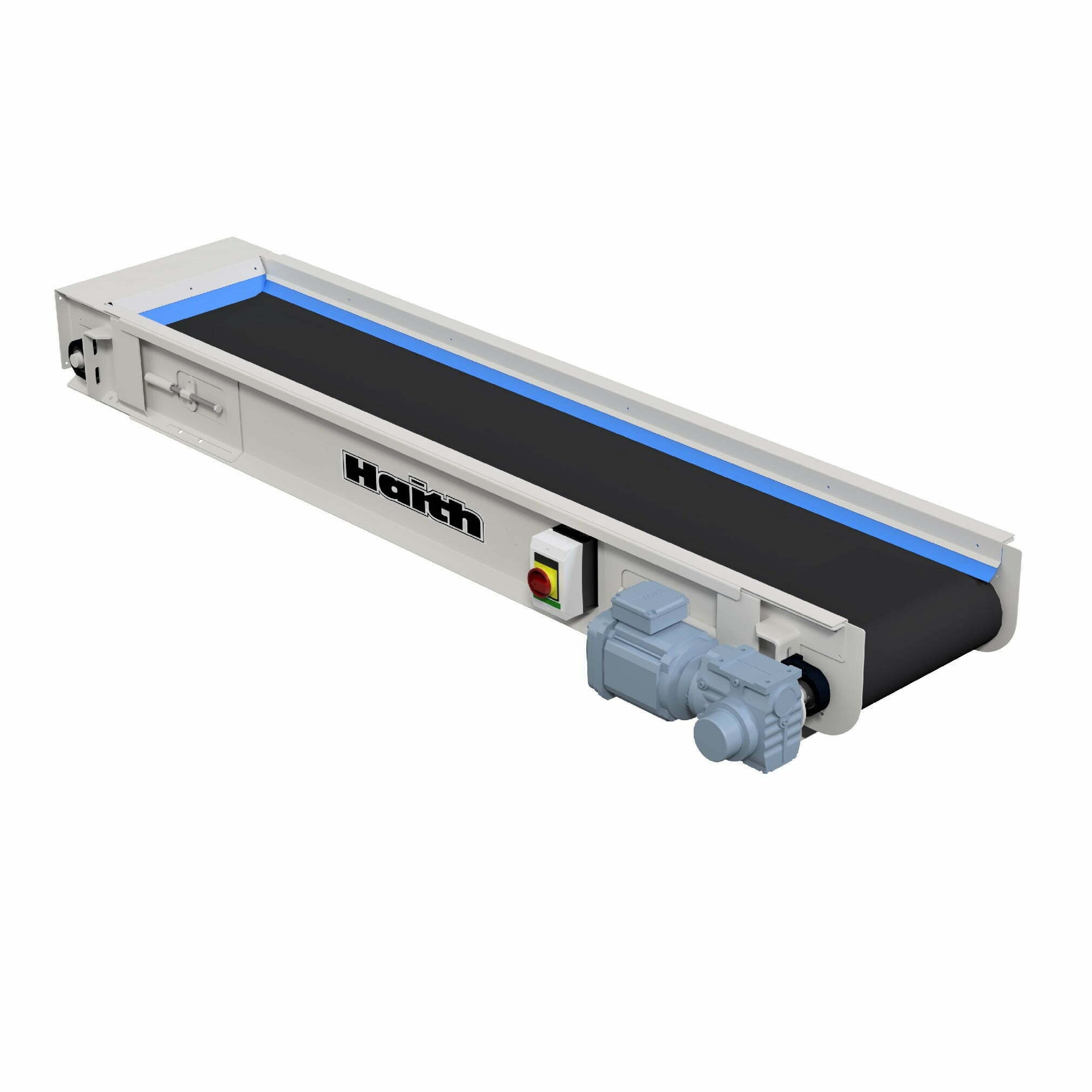

The semi trough conveyors and elevators have an additional set of rollers built within the chassis. When the belt is running along the additional rollers it forms a trough forcing the product into the centre of the belt, this allows the conveyor to hold more volume and reduces spillage.

These conveyors are mainly found at intake and aggregate plants where there are high volumes of product, material and heavy soil content. The conveyor chassis itself has thicker side walls than the standard packhouse conveyor and heavier duty construction.

Standard features

- Black rubber belt

- 75/140mm high skirting - stainless steel with seal

- Drive and driven rollers with shaft clamping elements

- External bearing design to aid access

- 50mm high cleats @ 300mm pitch/70mm high angled cleats @ 150mm pitch

Optional features

- Fixed speed or electronic/manual variable speed 3 phase shaft mounted geared drive

- Tubular support legs with adjustable feet

- Lockable castors

- Swan neck and return roller

- Belt scraper

- Under belt BZP/stainless steel support rollers

- Stainless steel bearing inserts, composite housings (idle and drive rollers

- Idle and drive rollers - stainless steel construction

- Infeed chute

Request more information

on this machine