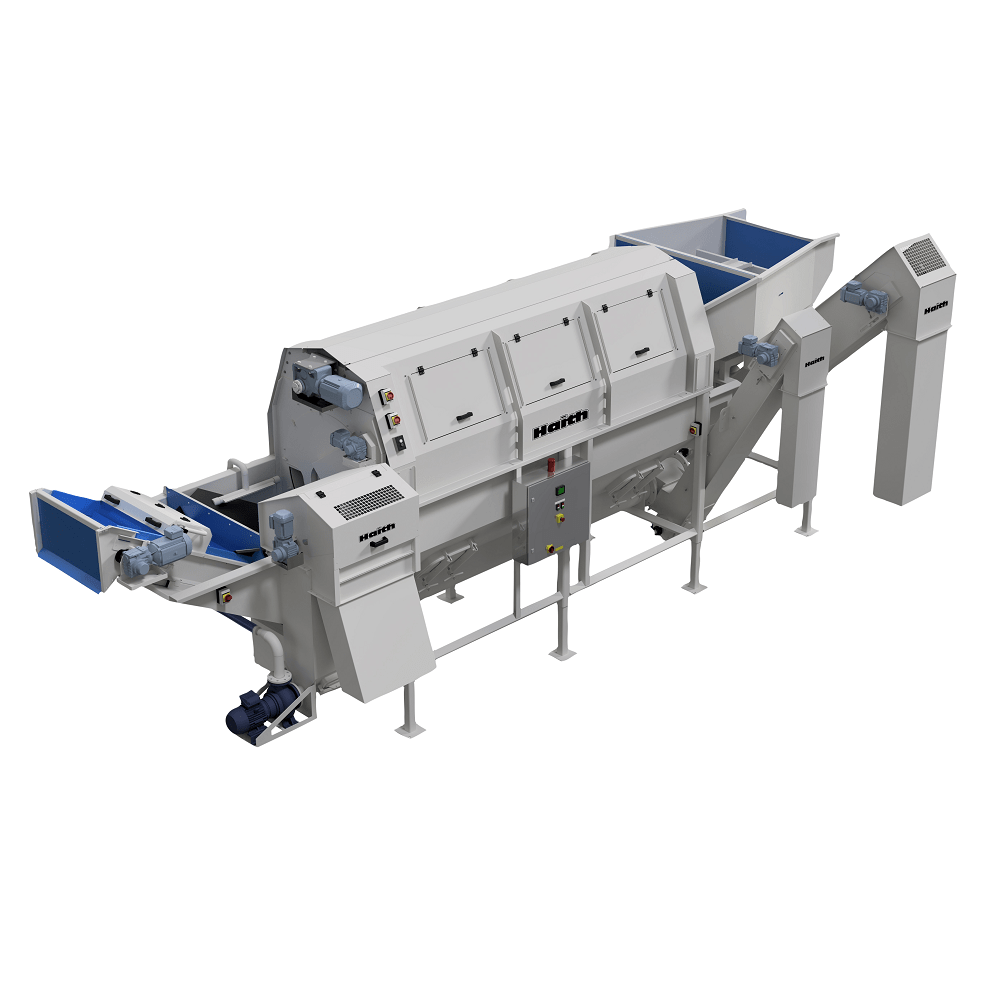

Developed in the early 2000s, Haith’s belt drive polishers have proven to be a popular machine throughout the world. Polishing the surface of the vegetable removes any soil and minor defects thus improving the appearance, extending shelf-life and adding value to the crop.

The produce gently enters a rotating barrel which is made up of a series of nylon brush rollers which counter-rotate independently, the speed of which is controlled by two independent drives located on either side of the machine. Water is sprayed onto the crop along the length of the barrel to maximise cleaning.

The machine is designed to be low maintenance with limited moving parts, triple sealed bearings, quick release brush rollers and full-length inspection doors, this results in ultra reliability, low running costs and minimal downtime.

The barrel is suspended on twin banded ‘V’ belts for a quiet operation.

Standard features

- Heavy duty construction

- Variable speed inverter controlled drives

- External grease points

- Triple sealed bearings

- Full length access doors

- Cooper split bearings on top shaft

- Pneumatic jack system

- Fresh water spray bars

Optional features

- Water recirculation base tank

Request more information

on this machine