Geoff Haith designed and manufactured what we believe to be the worlds first spokeless barrel washer in the 1970’s. Since then, our market leading barrel washers have proven to be the preferred choice for farmers, packers and processors around the world.

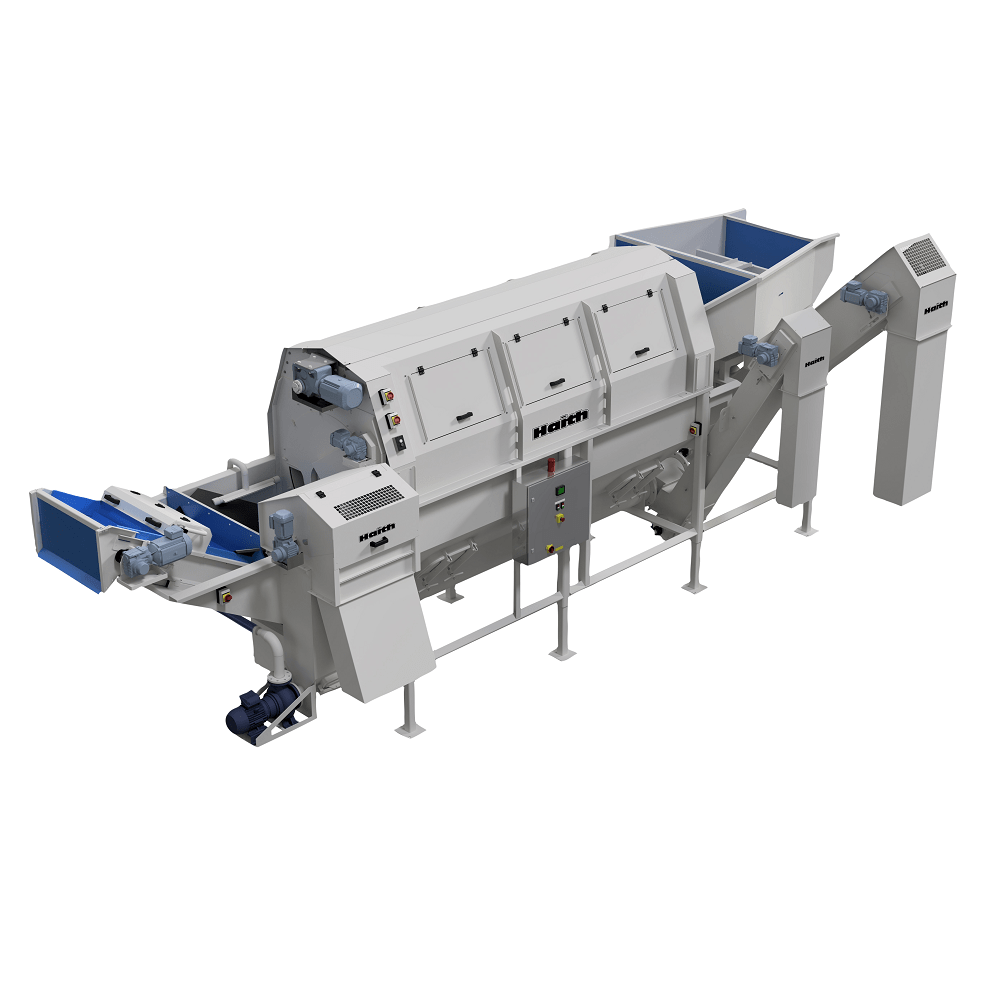

The Haith Barrel Washer is a robust, reliable and efficient machine. As the barrel rotates in the water, vegetables gently rub against each other and the barrel cleaning the surface of the crop. The barrel is fully pintle lined inside to maximise washing performance.

A discharge elevator removes the crop from the water, which can be set at a chosen outfeed height, with a fresh water spray bar giving the product a final rinse before further processing.

The highest quality of washing combined with an innovative, robust, maintenance friendly design.

Speak to our specialists

Call us on 01302 831911 and chat to a member of our team for more information about our industrial food handling equipment.

Standard features

- External bearings throughout for longevity and ease of maintenance

- Touch screen HMI to control all functions

- Variable speed barrel drive

- Fully pintle lined barrel to maximise cleaning of crop

- High efficiency electric drives

- Fresh water spray bar to rinse the crop on exit

- Heavy duty top shaft with SEW drive & TorqLOC® shaft mounting system

- Hygienic exoskeleton design

Optional features

- Integrated de-stoner

- Cooper split bearings on top shaft

- Floating debris removal system - for the removal of wood, plastic & hollow heart potatoes

- Sludge removal system with full length auger and scraper elevator - reduced water consumption

- Digital remote panel for the outfeed door

Request more information

on this machine

Speak to our specialists

Call us on 01302 831911 and chat to a member of our team for more information about our industrial food handling equipment.