Details

Features

Gallery

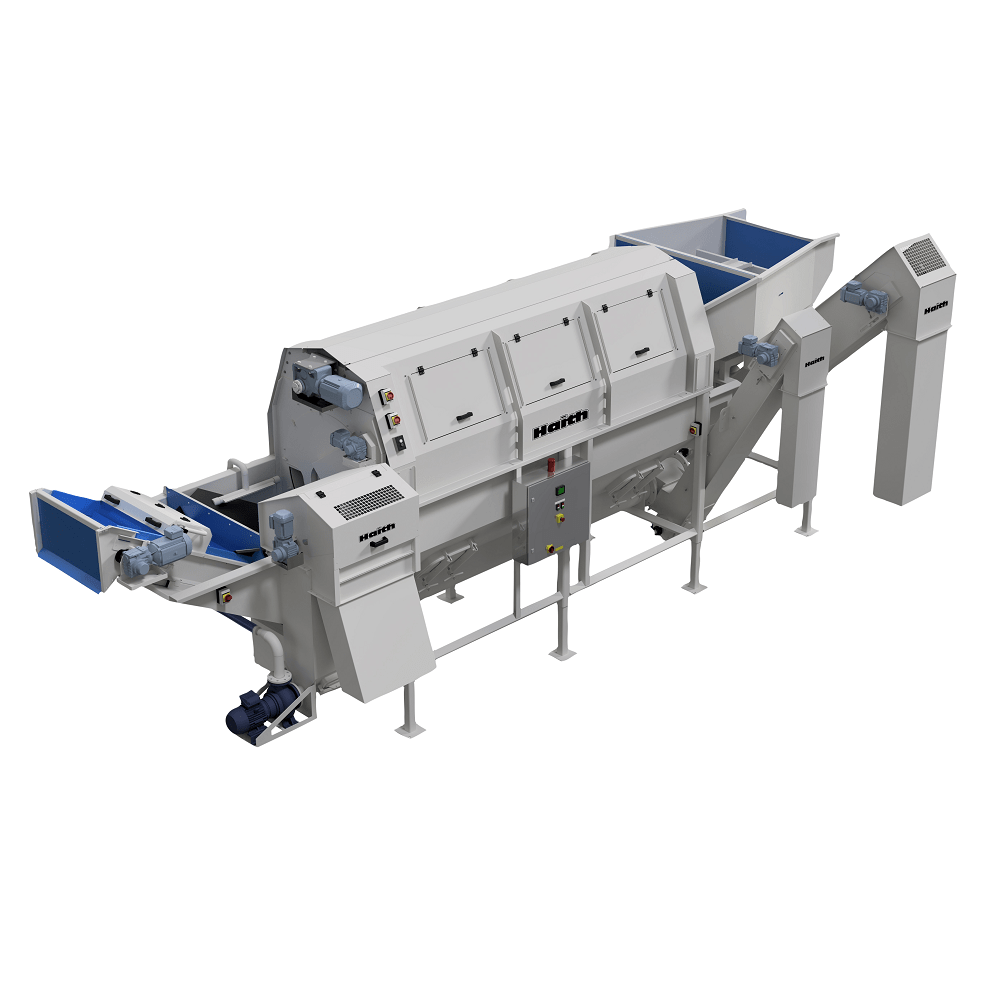

Geoff Haith designed and patented the Flume De-Stoner in 1971 and it is still being manufactured to this day.

The principle of this machine is to remove any stone and heavy clods from the vegetables before washing to eliminate any potential damage that may be caused to the crop or equipment further down the system.

Produce enters the machine and goes over an uplift of water which is controlled via a variable speed pump.

The different densities allow the crop to float over and the stones to sink down to the discharge elevator to be removed from the product flow. The produce is dewatered before entering the next process in the line.

Standard features

- Operating widths up to 900mm

- High efficiency pump

- Stainless steel wedge wire de-watering screen

- Stone discharge elevator

- Washer mounted or freestanding

Optional features

- Sludge discharge auger

- Stainless or mild steel construction

Request more information

on this machine